Looking for a lightweight, hygienic, moisture-resistant, and cheap wall or ceiling covering? Then you should pay attention to the plastic panels, which, in addition to everything, also have an excellent appearance. They are often used for wall cladding in the kitchen, in the bathroom, and on the balcony, and for finishing the ceiling in the bathroom and other rooms, often plastic panels are used in non-residential premises. For each of these areas of application, panels of a certain size, color, and relief will be appropriate. With a variety of materials and features of the choice of plastic panels, we will try to figure it out.

1. What Are the Pros and Cons Of Plastic Panels?

The basis to produce plastic panels is solid polyvinyl chloride, which is characterized by maximum resistance to fire. The material is made by extrusion, between two painted or varnished surfaces there is a space consisting of numerous longitudinal honeycombs formed by stiffeners.

The main advantages of PVC panels

- Moisture resistance, hygiene, antistatic, ease of care.

- Environmental friendliness.

- Fire resistance and resistance to temperature extremes.

- Good soundproofing qualities.

- A huge selection of patterns and textures, allows you to organize the interior in any style.

- Simple installation, which almost anyone can handle.

- Low price.

Considering plastic panels as a material for facing the ceiling or walls, you need to be aware that it also has some disadvantages:

- Low strength. It is easy to leave a scratch, dent, or another kind of damage on the surface of the material.

- At first, the panels may emit a specific smell.

- The material has a limited scope and is suitable for those rooms where strength is not as important as moisture resistance, fire resistance, and decorative effect.

2. Joint of plastic panels

Depending on the type of joint, plastic panels are:

- Seamless.

- Suture.

Seamless PVC board can be called very conditionally since the joint will still be noticeable, but the surface itself will be smooth because the visibility of the joint between the panels is not provided for by the decor. Of course, you should not expect that the ceiling, finished with such panels, will be as smooth as stretch or plasterboard, but by using special sealants, you can achieve very good results in terms of aesthetics.

The seam panels feature a special embossed joint to give the surface an interesting decorative effect. Often such plastic panels imitate wooden lining. There are also tile panels on sale: experts recommend using square elements with a side of 30-98 cm. In addition, you can find rusticated plastic panels on sale, they are something between the seam and seamless panels, but they are not very common.

3. Types Of Wall Panels for Their Intended Purpose

The most important and, at the same time, conditional division of wall panels is the division into ceiling and wall panels. No one forbids the use of wall panels for finishing the ceiling and vice versa. The difference between these types of panels is found only in the difference in the main parameters.

The thickness of the wall panels is 8-10 mm, and the length can be, 2.7 m, 3 m, or even 6 m. the thickness of 8 mm, now manufacturers are constantly reducing, so it is easy to find panels with a thickness of 7 mm and even 4-5 mm on sale.

4. Surface Type

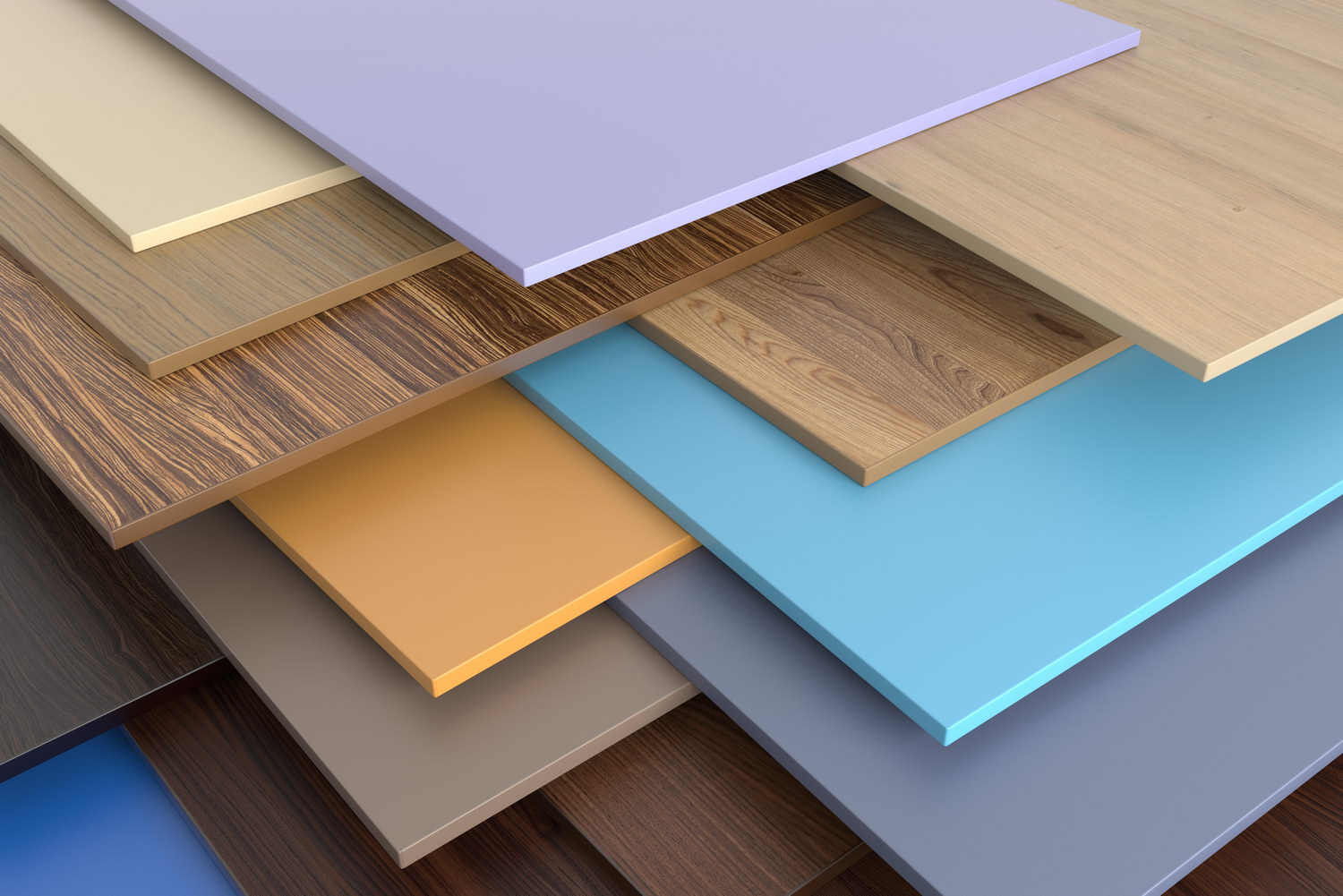

One of the main advantages of plastic panels is the variety of designs. On sale, you can find both the simplest and cheapest white panels, as well as materials painted in any color, but the most interesting options are those that have some kind of pattern or imitate wood, stone, or other noble surfaces.

All plastic panels according to the type of surface can be divided into:

- Matte.

- Glossy.

- Semi-gloss.

In terms of technical characteristics, all these panels are exactly the same, and depending on your own preferences, you can choose a panel with the required surface.